The trumpet is certainly one of the most versatile musical instruments. It can fit into an orchestra or concert band, marching band or drum and bugle corps, jazz or blues band. And it’s a good choice of instrument for the beginning or young musician.

Trumpets are almost always made entirely of brass, apart from a few minor components. And if properly maintained, a quality horn will typically retain its value over time.

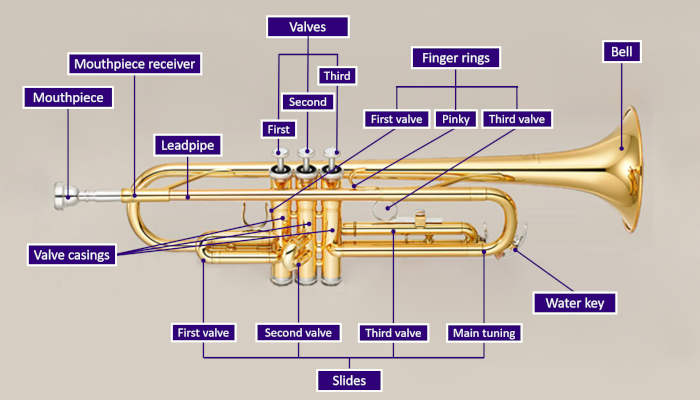

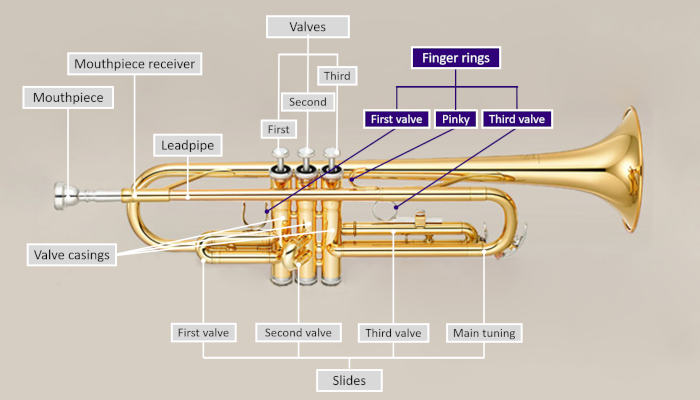

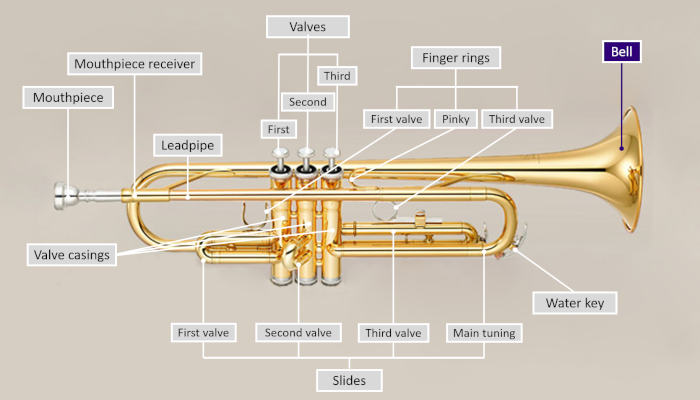

The first step to mastering the instrument is understanding how the different parts of a trumpet work together. Here we’ll be looking at the B♭ trumpet, the most common type.

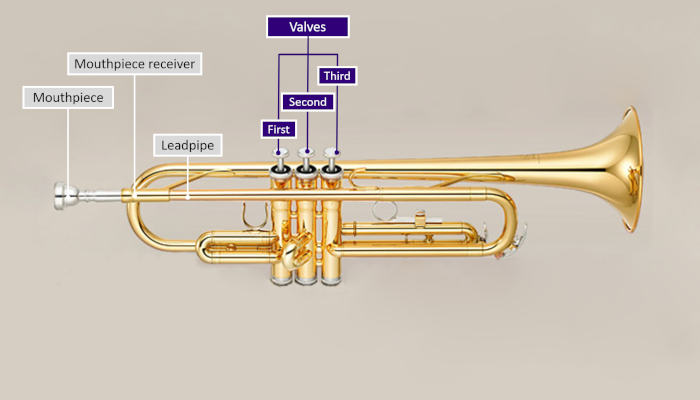

Trumpet mouthpiece

The mouthpiece is the interface between the player and the instrument. It’s also probably the most complex part of a trumpet (related: Trumpet Mouthpiece Sizes, Shapes and Features). The interplay of exhaled air and controlled lip vibrations create the sound that is refined and modulated along its path through the trumpet until it exits the bell as music.

A trumpet player may own several mouthpieces, each for different styles or technical requirements of the music.

Of all the various trumpet parts, the mouthpiece is the most personal. For sanitary reasons, never use another person’s mouthpiece without sterilizing it before and after use. The easiest way to clean and sterilize a trumpet mouthpiece is to immerse it in a pan of boiling water for 5 minutes.

Mouthpiece receiver

The mouthpiece receiver is the hole in the end of the leadpipe into which the mouthpiece is inserted. Take care to keep dirt and debris from entering the trumpet through here.

Never force a mouthpiece into the receiver. If it gets stuck, you may need to use a mouthpiece puller device or take the instrument to a repair shop and pay someone to remove it for you.

Leadpipe

The leadpipe is the first straight piece of pipe that extends from the mouthpiece to the first bend in the tubing. This section of the horn has a great impact on the color and timbre, or sound quality, of the instrument. The rate a leadpipe tapers affects the resistance to blowing air into the trumpet, as well as the resulting sound.

Professional trumpet players often replace the leadpipe that came with their instrument with one of a different diameter or taper rate. A technician at a music repair shop can typically make this change for you.

Trumpet valves

Trumpets are equipped with three piston valves which change the pitch of the notes when their buttons are depressed. They have finely machined holes that divert the sound of a note being played through sets of pipes, the valve slides, of varying lengths.

When a valve is depressed, air is diverted to the valve’s corresponding valve slide, the trumpet’s active pipe is lengthened and the pitch drops. When none of the valves are engaged, the air bypasses all three tuning slides.

As with the slides, regular cleaning and lubrication are vital to keeping the valves operating smoothly and avoiding getting stuck (related: Trumpet Valve Stuck? Here’s How to Fix It).

First valve

The first valve is the one closest to the musician. Depressing this valve will divert the air through the first valve slide, lowering the pitch of the note a full musical step (two semitones), or two notes lower on piano.

Second valve

The trumpet’s second valve is the middle of the three valves. Pressing down this valve will divert the air through the second valve slide, lowering the pitch of the note by a half step (one semitone), or one note lower on piano.

You may notice the second valve slide is roughly half the length of the first. This makes sense because the longer the piping, the lower the pitch. Since the first valve slide is double the length of the second, depressing the first valve lowers the pitch twice as much as depressing the second valve.

Third valve

The third valve is the one furthest from the musician during play. Pressing down this valve will divert the air through the third valve slide, lowering the pitch of the note by 1.5 steps (three semitones), or three notes lower on piano.

Note that the third valve slide is about 1.5 times longer than the second valve slide. And engaging the third valve accordingly lowers the pitch by 1.5 times as much as engaging the second valve.

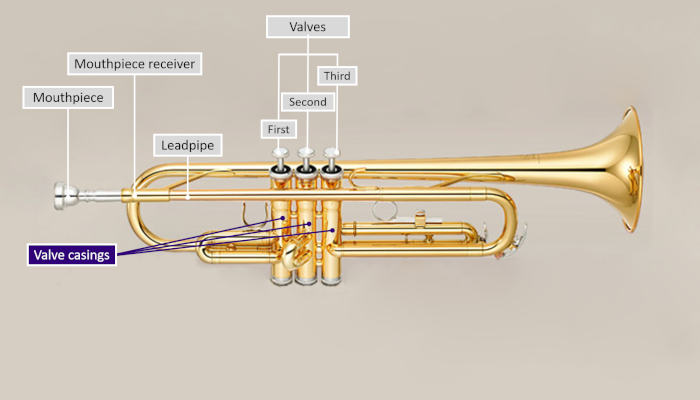

Valve casings

The valve casings are the cylindrical sleeves the valves fit into. These casings facilitate the deflection of air through the proper air paths in the trumpet.

Even minor dents to this area of the instrument will render the horn inoperable, as the valves will no longer freely travel up and down.

How often a musician should oil their trumpet valves is a subject of some debate. I’d suggest rinsing the valves in plain water and then oiling them every day. But if you don’t play your trumpet daily, you may still want to oil the valves a few times a week. Your choice of which valve oil to use will also affect how often to oil your valves.

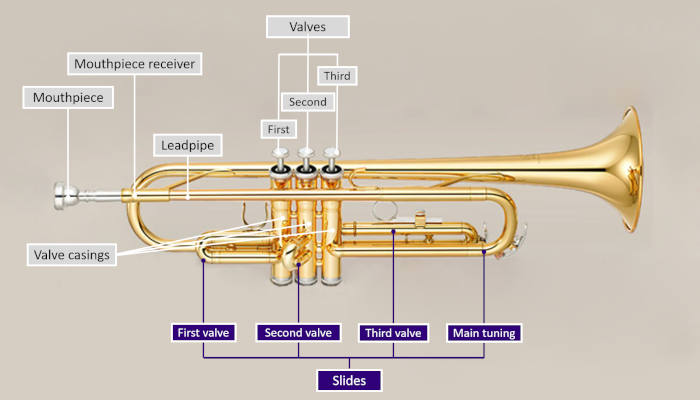

Trumpet slides

Slides are U-shaped pieces of tubing that are movable and removable. Trumpets tend to have four slides in all, each affecting pitch to different degrees.

The ends of each slide are a bit smaller in diameter than the rest of the pipe. This allows the pipes to join by sliding one inside the other.

Slides must be regularly cleaned and lubricated to work properly, as debris collecting on the slides can cause them to stick. Many musicians oil their trumpet slides once a month to keep them from sticking.

Main tuning slide

You’ll find the main tuning slide at the end of the trumpet near the bell. As the name suggests, this slide controls the trumpet’s tuning. The trumpeter can raise or lower the pitch when tuning with a band or orchestra by adjusting the tuning slide.

The main tuning slide is one of the most easily damaged parts of a trumpet. Take care to clean and lubricate it regularly. And avoid dropping it on a hard surface.

First valve slide

The first valve slide is part of the tubing assembly that branches off from the first valve casing and runs toward the player. As such, the first valve slide is only useful when using the first valve in combination with a note.

Certain notes, such as A or E, are sharp by default on most trumpets. And musicians use this slide to adjust the trumpet’s minor intonations.

The player presses down on the first valve, diverting air through the first valve slide. Then the player extends the slide to bring these notes into the correct pitch. Extending the slide lowers the pitch, while retracting the slide raises it.

A similar mechanism is at work when a musician moves the slide on a trombone to change its pitch while playing.

Second valve slide

The second valve slide is removable but fixed in position during play. And unlike the other slides mentioned so far, this one isn’t adjusted for tuning the instrument or changing intonation of individual notes while playing. Its main purposes are to:

- Make it easier to clean the instrument and reach the second valve to lubricate it when the valve is removed

- Extend the trumpet’s tubing to bring into tune all the notes involved with the second valve

Air is diverted through the second valve tubing when the player engages the second valve.

The second valve slide is also the point in the tubing commonly used to measure a trumpet’s bore size. Bore size can affect how a trumpet performs, and manufacturers usually list this measurement with a model’s other specifications (related: Trumpet Bore Size: How Much Does it Matter?).

Third valve slide

The third valve slide is part of the tubing assembly extending off from the third valve casing and running away from the player.

This slide functions much the same way as the first valve slide. Used predominantly on lower parts of the trumpet’s range, the third valve slide is only useful when using the third valve in combination with a note.

A D note, for example, is normally sharp on the trumpet by default. To reach concert D pitch, the player extends the third valve slide to correct the pitch.

Finger rings

Finger rings are metal loops attached at various points of the trumpet for easier handling. These are welded to the tubing and are made of a base metal plated with the same material as the rest of the horn.

It’s rare for finger rings to break off. But if one does break, the whole slide can usually be replaced at once, including the ring or thumb hook.

First valve ring

The first valve ring, sometimes called the first trigger, is a horseshoe-shaped hook attached to the first valve slide. It helps the player quickly engage the slide for intonation changes involving the first valve. The musician typically keeps their left thumb in this hook when playing.

Third valve ring

The third valve ring, sometimes called the third trigger, is a ring attached to the third valve slide. It helps the player quickly engage the slide for intonation changes involving the third valve. Most musicians keep their right ring finger in this ring while playing.

Pinky ring

Most trumpets also have a C-shaped ring welded to the top of the leadpipe called the pinky ring, or finger hook. Rather than activating a slide, musicians use this ring as a gripping point for the trumpet.

Inserting the fifth, or pinky, finger here helps the musician hold the instrument steady during play. The ring also enables the player to securely hold the horn in their right hand while turning a page of sheet music with their left.

Some players always keep their pinky finger in the ring while playing, which is improper technique. The pinky should rest lightly on top of the ring or be held freely.

Many players compensate for a poor or weak embouchure by pulling the horn harder into the mouth. This is especially true of players with under-developed mouth muscles for playing high notes. Excess mouthpiece pressure can cause poor tone quality or even injury to the player’s lips.

Water key

Saliva and condensed water vapor build up in the horn during play, which can cause a gurgling sound if left unchecked. The trumpet was designed with a water key, also known as a spit valve, to prevent this.

The water key is a hinged valve found on the far end of the main tuning slide which opens a small round hole in the horn. The musician clears any saliva or moisture by pressing this valve and blowing into the mouthpiece.

The water key has a small piece of rubber, cork or felt that covers the hole in the pipe. This small piece sometimes needs replacing when it wears out and no longer forms a proper seal.

Bell

The bell end of the horn is where the sound exits the instrument. The flare of the metal amplifies the sound and directs it toward the listener (related: Trumpet Bells and Their Differences).

You can use silver polish or another commercial cleaner to maintain the bell’s finish. A microfiber cloth can shine your horn up to a mirror finish. It’s best to wipe down the horn after each playing session.

Always use a horn stand or lay the instrument down on its side, with the valve casings facing upwards. Do not leave it standing on its bell. It could easily fall over or get scratched.

Conclusion

The trumpet is an excellent choice for novice and experienced musicians alike. As a wind instrument common to many styles of music, learning to play the trumpet can be very rewarding.

Take great care of your horn, and it may last you a lifetime. Disassemble and clean the trumpet parts regularly and keep them lubricated. And be mindful of where you set down and store your horn to keep the bell and other parts from being scratched or dented.

Quite an impressive article.

Very easy to follow and understand, on a sum what difficult instrument.

Illustrations help you understand the parts and techniques.